Mercury 250 Specifications

Browse online or download Specifications for Motor vehicle accessories & components Mercury 250. Mercury 250 Specifications User Manual

- Page / 120

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

- WARNING 1

- Warranty Message 2

- Mercury Premier Service 2

- TABLE OF CONTENTS 5

- WARRANTY INFORMATION 10

- GENERAL INFORMATION 20

- TRANSPORTING 39

- FUEL AND OIL 40

- FEATURES AND CONTROLS 45

- OPERATION 53

- MAINTENANCE 61

- Storage Preparation 82

- Refer to 83

- , preceding 83

- Gearcase 84

- Battery Storage 84

- TROUBLESHOOTING 85

- OWNER SERVICE ASSISTANCE 87

- OUTBOARD INSTALLATION 100

- BATTERY CABLE CONNECTIONS 105

- HOSE AND TUBING CONNECTIONS 106

- INSTALLING THE SHIFT CABLE 107

- MAINTENANCE LOG 120

Summary of Contents

iThank Youfor your purchase of one of the finest outboards available. Youhave made a sound investment in boating pleasure. Youroutboard has be

WARRANTY INFORMATION2Plan coverage is not transferable from one product to anotherproduct or for non‑eligible applications.The Certified Pre‑

OUTBOARD INSTALLATION921. Mark four mounting holes on the transom using the transomdrilling fixture.2757aabca - Drill guide holesb - Transom drillingf

OUTBOARD INSTALLATION93Fastening the Outboard to the TransomMOUNTING BOLTSOutboard Transom Mounting Hardware ‑ Supplied with OutboardPart Number Part

OUTBOARD INSTALLATION94CHECKING BOAT TRANSOM CONSTRUCTIONIMPORTANT: Determine the strength of the boat transom. Theoutboard mounting locknut

OUTBOARD INSTALLATION951. Apply marine sealer to shanks of bolts, not the threads.2. Fasten the outboard with the correct mounting hardware.Tig

OUTBOARD INSTALLATION96Electrical, Hoses, Control Cables, and Front ClampREMOTE WIRING HARNESSRoute the remote 14 pin boat harness through the

OUTBOARD INSTALLATION97Decal needs to be placed on or near battery box for future servicereference. One 5/16 in. and one 3/8 in. hex nut are supplied

OUTBOARD INSTALLATION98Dual OutboardsConnect a common ground cable (wire size same as enginebattery cables) between negative (–) termina

OUTBOARD INSTALLATION99This outboard has a speedometer water pick‑up located in theleading edge of the gearcase. If you want to use this wate

OUTBOARD INSTALLATION100Locating the Center Point of the Shift CableIMPORTANT: Locate the center point of the slack or lost motionthat exists in the s

OUTBOARD INSTALLATION1013. Mark the center on the shift cable midway between the forwardand reverse marks.4361aa - Center mark4. Align the cable en

WARRANTY INFORMATION33. Upon processing the warranty registration, Mercury Marinewill send registration verification by mail to the purchaser of

OUTBOARD INSTALLATION1022. Place the shift cable end guide on the anchor pin and adjustthe cable barrel so that it slips freely into the barrel holder

OUTBOARD INSTALLATION1032. Attach the throttle cable to the throttle lever. Secure with awasher and locknut. Tighten the locknut to the specified

OUTBOARD INSTALLATION104c. Place a thin piece of paper between the idle adjustmentscrew and the idle stop. The adjustment is correct when thepaper ca

OUTBOARD INSTALLATION1052. Place the neoprene wrap around the wiring, hoses, andcontrol cables, and place into the lower half of the front cla

OUTBOARD INSTALLATION1065. Reinstall the cowl seal.a29075a - RetainerFilling the Fuel SystemWhen starting an engine for the first time, or starting an

OUTBOARD INSTALLATION107Oil Injection Set‑UpFILLING OIL SYSTEM1. Fill the remote oil tank with the recommended oil. Refer to OilRecommendation. Tighte

OUTBOARD INSTALLATION108PRIMING OIL INJECTION PUMPBefore starting the engine for the first time, prime the oil injectionpump. Priming will remove any

OUTBOARD INSTALLATION109d. Turn the ignition key switch to the "ON" position for threeseconds. This operates the electric fuel pump.26846e.

OUTBOARD INSTALLATION110Trim In Pin! WARNINGOperating the boat at high speeds with the outboard trimmed toofar under can create excessive bow st

OUTBOARD INSTALLATION111The owner may decide to limit the trim in. This can beaccomplished by purchasing a stainless steel tilt pin

WARRANTY INFORMATION4CONDITIONS THAT MUST BE MET IN ORDER TO OBTAINWARRANTY COVERAGE: Warranty coverage is available only toretail customers

MAINTENANCE LOG112Maintenance LogRecord all maintenance performed on your outboard here. Be sureto save all work orders and receipts.Date Maintenance

WARRANTY INFORMATION5WHAT IS NOT COVERED: This limited warranty does not coverroutine maintenance items, tune ups, adjustments, normal wearand tear,

WARRANTY INFORMATION6DISCLAIMERS AND LIMITATIONS:THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR APARTICULAR PURPOSE ARE EXPRESSLY DISCLAIME

WARRANTY INFORMATION7CONDITIONS THAT MUST BE MET IN ORDER TO OBTAINWARRANTY COVERAGE: Warranty coverage is available only toretail customers

WARRANTY INFORMATION8WHAT IS NOT COVERED: This limited warranty does not coverelectrical system corrosion; corrosion resulting from damage,corro

WARRANTY INFORMATION9DISCLAIMERS AND LIMITATIONS:THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR APARTICULAR PURPOSE ARE EXPRESSLY DISCLAIME

WARRANTY INFORMATION102. Factory installed jet drive units ‑ Specific parts excluded fromthe warranty are: the jet drive impeller and jet dri

WARRANTY INFORMATION1112.Lower unit and/or propeller damage caused by striking asubmerged object is considered a marine hazard.13.Water enteri

iiWarranty MessageThe product you have purchased comes with a limited warrantyfrom Mercury Marine, the terms of the warranty are set forth in theWarra

GENERAL INFORMATION12Boater's ResponsibilitiesThe operator (driver) is responsible for the correct and safeoperation of the boat and

GENERAL INFORMATION13Boat Horsepower Capacity! WARNINGExceeding the boat's maximum horsepower rating can causeserious injury or death. Ove

GENERAL INFORMATION14When choosing a propeller, a full selection of aluminum andstainless steel propellers specifically designed for your out

GENERAL INFORMATION15Propellers are designated by the diameter, pitch, number ofblades, and material. The diameter and pitch are stamped (cast

GENERAL INFORMATION16• Adding 1 inch of pitch will reduce the full throttle RPM by 150to 200• Subtracting 1 inch of pitch will increase full throttle

GENERAL INFORMATION17! WARNINGStarting the engine with the drive in gear can cause serious injuryor death. Never operate a boat that does not

GENERAL INFORMATION18Lanyard Stop SwitchThe purpose of a lanyard stop switch is to turn off the engine whenthe operator moves far enough away from the

GENERAL INFORMATION19Important Safety Information: The purpose of a lanyard stop switchis to stop the engine when the operator moves far enough awayfr

GENERAL INFORMATION20Accidental or unintended activation of the switch during normaloperation is also a possibility. This could cause any, or

GENERAL INFORMATION21Shift outboard into neutral and shut off the engine before allowingpeople to swim or be in the water near your boat.Passenger Saf

iii• Provides timely service for all Mercury Marine customers.• Offers extended service hours and mobile service, whenappropriate.• Uses, disp

GENERAL INFORMATION22BOATS WITH FRONT MOUNTED, RAISED PEDESTALFISHING SEATSElevated fishing seats are not intended for use when the boat istraveling

GENERAL INFORMATION23! WARNINGWave or wake jumping can cause serious injury or death fromoccupants being thrown within or out of the boat. Avoid wave

GENERAL INFORMATION24• The boat could move suddenly in a new direction. Such asharp change in direction can cause occupants to be thrownout

GENERAL INFORMATION25! WARNINGCarbon monoxide poisoning can lead to unconsciousness, braindamage, or death. Keep the boat well ventilated while at res

GENERAL INFORMATION26WHILE BOAT IS MOVINGab21628a - Running the boat with the trim angle of the bow too highb - Running the boat with no forward hatch

GENERAL INFORMATION27Know and obey all nautical rules and laws of the waterways. Boatoperators should complete a boating safety course. Courses areoff

GENERAL INFORMATION28Report accidents. Boat operators are required by law to file aBoating Accident Report with their state boating law enfo

GENERAL INFORMATION29Models 200 3.0 Liter 225 250Cylinder bore 92.1 mm (3.626 in.)Stroke 76.2 mm (3.000 in.)Recommendedspark plugChampion QL77CC1.Spar

GENERAL INFORMATION30Component Identificationabcdefghij29304a - Top cowlb - Bottom cowlc - Water pump indicatorholed - Driveshaft housinge - Anti‑vent

TRANSPORTING31Trailering Boat/OutboardTrailer your boat with the outboard tilted down in a verticaloperating position.If additional ground c

iv

FUEL AND OIL32Fuel RecommendationsIMPORTANT: Use of improper gasoline can damage yourengine. Engine damage resulting from the use of im

FUEL AND OIL33The fuel system components on your Mercury Marine engine willwithstand up to 10% alcohol content in the gasoline. We do notknow what p

FUEL AND OIL34IMPORTANT: Oil must be NMMA certified TC‑W3 2‑Cycle oil.Mercury or Quicksilver Premium TC‑W3 2‑Cycle oil isrecommended for thi

FUEL AND OIL35IMPORTANT: Always make sure the oil tank caps are threadedon tight. An air leak will prevent oil flow to the engine.2723Filling Engine

FUEL AND OIL36Always stop engine before refilling tanks.Do not completely fill the fuel tanks. Leave approximately 10% ofthe tank volume unfilled.

FEATURES AND CONTROLS37Remote Control FeaturesYour boat may be equipped with one of the Mercury Precision orQuicksilver remote controls shown. If not,

FEATURES AND CONTROLS38Warning SystemThe outboard warning system incorporates a warning horn insidethe boat. The warning horn may be located i

FEATURES AND CONTROLS39Warning HornFunction Sound DescriptionCooling SystemProblemContinuous Engine Guardian System is activated.Power limit will vary

FEATURES AND CONTROLS40If Guardian System has been activated, reduce throttle speed. Thehorn will turn off when throttle speed is within the allowable

FEATURES AND CONTROLS41POWER TRIM OPERATIONWith most boats, operating around the middle of the trim range willgive satisfactory results. However, to t

TABLE OF CONTENTSvWarranty InformationTransfer of Warranty...1Transfer of Mercury Pro

FEATURES AND CONTROLS42! WARNINGOperating the boat at high speeds with the outboard trimmedtoo far under can create excessive bow steer, resulting in

FEATURES AND CONTROLS433. Disengage the tilt support lever, by raising the outboard off thesupport lever and rotating the lever down. Lower the outboa

FEATURES AND CONTROLS44AUXILIARY TILT SWITCHThe auxiliary tilt switch can be used to tilt the outboard up or downusing the power trim system.a27779a -

OPERATION45Pre‑Starting Check List• Operator knows safe navigation, boating, and operatingprocedures.• An approved personal flotation device of

OPERATION46Operating in Saltwater or Polluted WaterWe recommend that you flush the internal water passages of youroutboard with fresh water after each

OPERATION47Setting Trim Angle While Running Engine at IdleSpeedThe exhaust relief hole on the outboard may become submergedif the outboard is trimmed

OPERATION48b. Change engine speed approximately every two minutes,and avoid continuous operation at idle speed for more thanten minutes. Short bursts

OPERATION492. Open the fuel tank vent screw (in filler cap) on manual ventingtype fuel tanks.197483. Position the fuel line primer bulb so the arrow o

OPERATION50b. Turn the ignition key switch to the "ON" position for threeseconds. This operates the electric fuel pump.c. Turn the ignition

OPERATION51IMPORTANT: If no water is coming out of the water pumpindicator hole, stop engine and check cooling water intake holesfor obstruc

TABLE OF CONTENTSviFuel and OilFuel Recommendations...32Oil Recommendation...

OPERATION52Stopping the EngineReduce engine speed and shift outboard to neutral position. Turnignition key to "OFF" position.26843

MAINTENANCE53Outboard CareTo keep your outboard in the best operating condition, it isimportant that your outboard receive the periodic insp

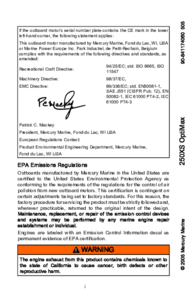

MAINTENANCE54EPA EmissionsEMISSION CERTIFICATION LABELAn emission certification label, showing emission levels andengine specifications directl

MAINTENANCE55• Inspect the outboard for tightness to the boat transom. If anylooseness of the outboard or mounting fasteners exist,retorque the

MAINTENANCE56•Check control cable adjustments.1.• Check tightness of bolts, nuts, and other fasteners.EVERY 300 HOURS OF USE OR THREE YEARS• Replace

MAINTENANCE57Top Cowl Removal and InstallationREMOVAL1. Pull out the front cowl latch.284312. Lift front of cowl to clear front latch and push toward

MAINTENANCE58Before servicing any part of the fuel system, stop engine anddisconnect the battery. Drain the fuel system completely. Use anap

MAINTENANCE59d. Lubricate the sealing ring on the filter with oil. Thread onthe filter and tighten securely by hand. Reconnect the wireto the filter.I

MAINTENANCE60Description Nm lb. in. lb. ft.Special washer head bolt 27 20Nylon insert locknut "d" 27 20Nylon insert locknut "c" Ti

MAINTENANCE61Open the fuse holder and look at the silver colored band inside thefuse. If band is broken, replace the fuse. Replace fuse with a newfuse

TABLE OF CONTENTSviiMaintenanceOutboard Care...53EPA Regulations...

MAINTENANCE62The gearcase has two corrosion control anodes, one on each side.A third anode is installed on the bottom of the transom bracketassem

MAINTENANCE631. Shift outboard to neutral (N) position.N 26838IMPORTANT: Refer to Spark Plug Inspection and Replacementfor removing spark plug leads.2

MAINTENANCE644. Place a block of wood between gearcase and propeller to holdpropeller and remove propeller nut.269015. Pull propeller straight off sha

MAINTENANCE657. Flo‑Torq I drive hub propellers ‑ Install forward thrust hub,propeller, continuity washer, rear thrust hub, propeller

MAINTENANCE6610.Secure propeller nut by bending three of the tabs into thethrust hub grooves.26945Spark Plug Inspection and Replacement! WAR

MAINTENANCE673. Set the spark plug gap to specifications.27848Spark Plug Gap Spark plug 0.90 mm (0.035 in.)4. Before installing spark plugs, clean o

MAINTENANCE68Tube RefNo.Description Where Used Part No.94Anti-CorrosionGreasePropeller shaft 92-802867Q 1952-4-C with Teflon Propeller shaft 92-802859

MAINTENANCE69• Alternator Belt Tensioner Pivot Shaft ‑ Lubricate throughfitting.29300• Swivel Bracket ‑ Lubricate through fitting.• Tilt Support Lever

MAINTENANCE70• Steering Cable Grease Fitting (if equipped) ‑ Rotatesteering wheel to fully retract the steering cable end intothe outboard tilt

MAINTENANCE712. Remove fill cap and check fluid level. The fluid level should beeven with the bottom of the fill hole. Add Quicksilver orMer

TABLE OF CONTENTSviiiOwner Service AssistanceLocal Repair Service...79Service Away from

MAINTENANCE724. Remove vent plug and fill/drain plug and drain lubricant.ab22692a - Vent plug b - Fill/drain plugGEARCASE LUBRICANT CAPACITYGearcase l

MAINTENANCE734. Stop adding lubricant. Install the vent plug and sealing washerbefore removing the lubricant tube.5. Remove lubricant tube and reinsta

STORAGE74Storage PreparationThe major consideration in preparing your outboard for storage isto protect it from rust, corrosion, and damage caused by

STORAGE75Flushing Device 91‑44357Q 29192Attaches to the water intakes;provides a fresh waterconnection when flushing thecooling system or operating th

STORAGE76Gearcase• Drain and refill the gearcase lubricant (refer to Maintenance ‑Gearcase Lubrication).Positioning Outboard for StorageStore outboard

TROUBLESHOOTING77Starter Motor Will Not Crank the EnginePOSSIBLE CAUSES• Blown 20 amp fuse in the starting circuit. Refer toMaintenance.• Out

TROUBLESHOOTING78Engine Runs ErraticallyPOSSIBLE CAUSES• Spark plugs fouled or defective. Refer to Maintenancesection.• Incorrect setup and adj

OWNER SERVICE ASSISTANCE79Local Repair ServiceAlways return your outboard to your local authorized dealer shouldthe need for service arise. Only

OWNER SERVICE ASSISTANCE80• Model and serial number of your outboard• The name and address of your dealership• Nature of problemMercury Marine Service

OWNER SERVICE ASSISTANCE81Asia, SingaporeTelephone 5466160 Mercury Marine Singapore72 Loyang WaySingapore, 508762Fax 5467789

WARRANTY INFORMATION1Transfer of WarrantyThe limited warranty is transferable to a subsequent purchaser, butonly for the remainder of the unused porti

OUTBOARD INSTALLATION82Important InformationBEFORE STARTING THE ENGINENOTICELack of oil pressure in the system can cause severe internalengi

OUTBOARD INSTALLATION83Boat Horsepower Capacity! WARNINGExceeding the boat's maximum horsepower rating can causeserious injury or death. O

OUTBOARD INSTALLATION84Some accessories not manufactured or sold by Mercury Marineare not designed to be safely used with this outboard or outboardope

OUTBOARD INSTALLATION85Installation Specifications18552aaba - Minimum transom openingb - Engine centerline for dual engine ‑ 66.0 cm (26 in.)Minimum T

OUTBOARD INSTALLATION862. Thread the lifting eye into the flywheel hub for a minimum offive turns.24290aa - Lifting eye3. Connect a hoist to the lifti

OUTBOARD INSTALLATION87Tube RefNo.Description Where Used Part No.952-4-C with TeflonO-ring seal andentire cable end92-802859A 12. Insert steering cabl

OUTBOARD INSTALLATION88! WARNINGImproper fasteners or improper installation procedures can resultin loosening or disengagement of the steering link ro

OUTBOARD INSTALLATION893. Torque the head bolt, then the locknut to specifications.Description Nm lb. in. lb. ft.Cable coupler nylon locknut "d&q

OUTBOARD INSTALLATION90Determining Recommended Outboard MountingHeight(20 in.) (21 in.) (22 in.) (23 in.) (24 in.) (25 in.) (19 in.) 10 20 30 40 50

OUTBOARD INSTALLATION91NOTICE1. The outboard should be mounted high enough on the transom so theexhaust relief hole will stay at least 25.4 mm (1 in.)

More documents for Motor vehicle accessories & components Mercury 250

(179 pages)

(179 pages)

Comments to this Manuals